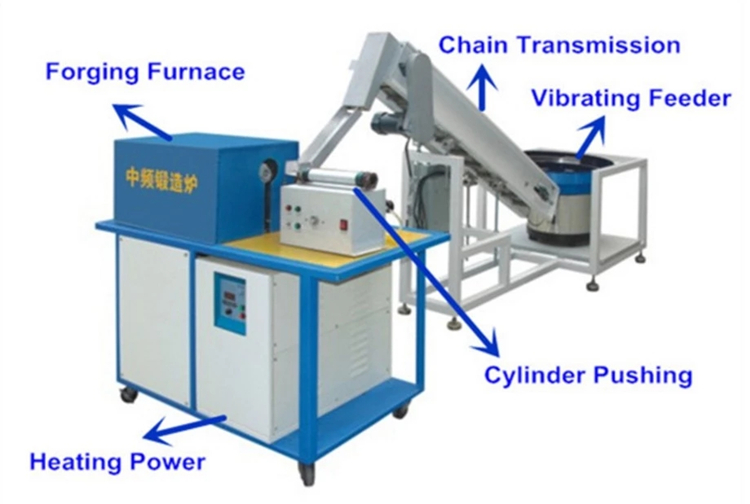

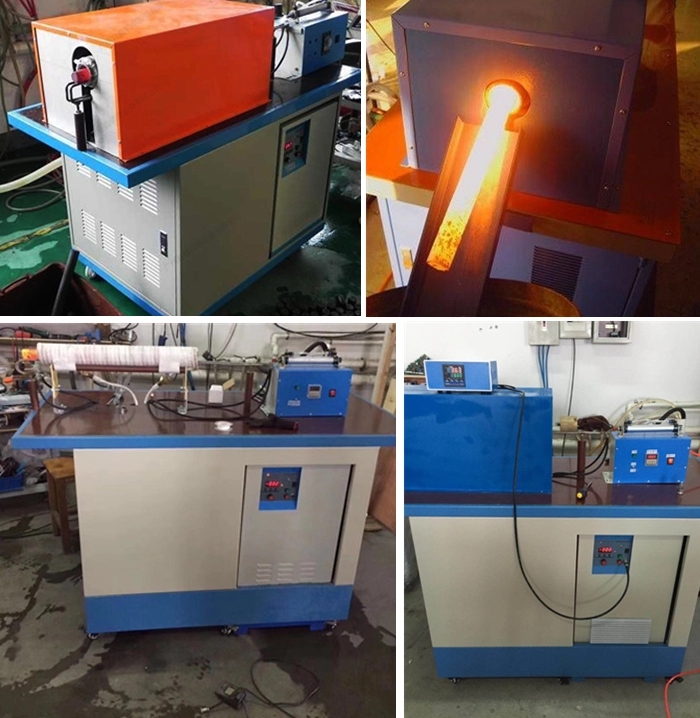

Billets Automatic induction heating furnace

• Whole processes including the rod picking up, rod selecting, rod pushing and rod sending out, heating and temperature controlling are all automatically controlled by PLC device.

• A wide range of rod size from Φ20 to Φ60 and length from 50 to 250mm.

• The temperature of the rod can be exactly controlled to achieve high quality of the parts.

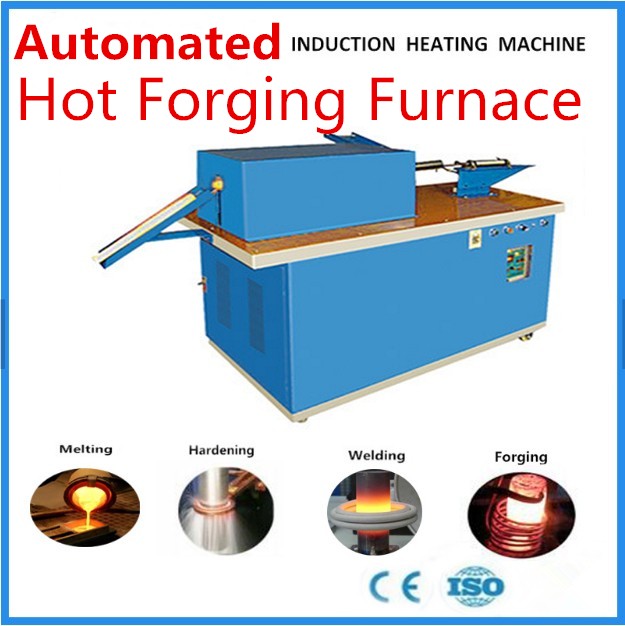

Hot Forging Furnace for Heating rods/bars/bolts/shafts/nuts

Rod induction forging furnace with auto-feed system

Used for the automatically heating of steel, brass, aluminum and other metal rods.

Characteristics

• Whole processes including the rod picking up, rod selecting, rod pushing and rod sending out, heating and temperature controlling are all automatically controlled by PLC device.

• A wide range of rod size from Φ10 to Φ60 and length from 50 to 550mm.

• The temperature of the rod can be exactly controlled to achieve high quality of the parts.

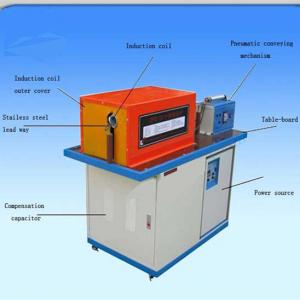

The composing of the MF induction forging furnace:

1) MF induction heating generator.

2) Compensating capacitor

3) Heating coil and guide rail and coil cover.

4) Pneumatic rod feeder.

5) Working table and stander.

Options:

1) Infrared sensor,

2)Temperature controller.

3)Automatic rod picking and feeding systems.

4)Water cooling systems.

5)Others

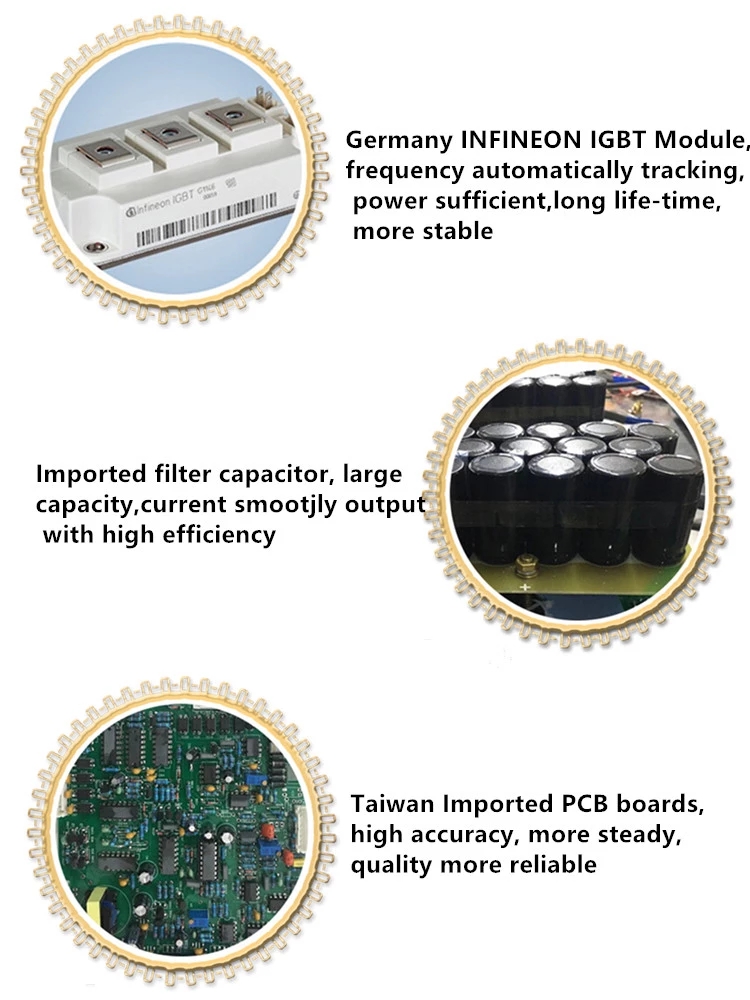

Main Parts

Heating Ability of Different Model

| Models | Max. Power (KW) | Heating capacity of common metal materials |

Hot Forging Furnace | Heating steel and stainless steel materials to 1100 ℃ Heating brass materials to 700 ℃ | |

| DFTZ-25 | 25 | Suitable for ¢ 12-30mm bar heating |

| DFTZ-35 | 35 | Suitable for ¢ 12-30mm bar heating |

| DFTZ-45 | 45 | Suitable for ¢ 12-30mm bar heating |

| DFTZ-70 | 70 | Suitable for ¢ 15-50mm bar heating |

| DFTZ-90 | 90 | Suitable for ¢ 15-50mm bar heating |

| DFTZ-110 | 110 | Suitable for ¢ 15-50mm bar heating |

| DFTZ-160 | 160 | Suitable for ¢ 15-90mm bar heating |

| DFTZ-200 | 200 | Suitable for ¢ 15-90mm bar heating |

| DFTZ-250 | 250 | Suitable for ¢ 30-150mm bar heating |

Advantages of hot forging furnace:

● Ultra-small size, movable, covering only 0.6 square meters.

● Convenient to use with any forging and rolling equipment and manipulator;

● It is very convenient to install, debug and operate.

● Can be heated to the required temperature in a very short time, greatly reducing metal oxidation, saving materials and improving forging quality;

● It can work uninterrupted for 24 hours, the heat penetration is even and better;

● Environmental protection, meeting environmental protection requirements, eliminating the trouble of environmental protection inspection;

● Power saving, compared with SCR medium frequency, not only small size, easy maintenance, but also 15-20% power saving.

● It is convenient to replace the furnace body to meet the different requirements of the overall heating of the bar or the heating of the end;

Certifications

FAQ

01.How to choose your models?

First to provide me the size, pictures and technology requirements. Our engineers with more than 12 years of experience will recommend you the suitable machine according to your workpiece. We provide detailed evaluation plans for free! (Add my WhatsApp: +8613113688127, talk now )

02.Can you produce according to the samples?

Yes, please send us your samples by express, we can evaluate by your samples or technical drawings. We can build the molds and fixtures. We provide Free test videos and reports to you,

03.How about your standard delivery date?

For small batch orders, we have storage delivery within three days. Large batch orders, delivery within 7-12 days, Our company provide just-in-time delivery.

04. Do you have CE, ISO9001 certificate?

Yes, we have.

05. Where is your factory?

Our factory located in Shenzhen city, next to HongKong, convenient in air, sea shipment.

06. If I buy the machine from you, how to install and operate?

our machines have manual and installation schematic diagram. If necessary, I can also send you to install video, we can also provide on-site installation services, but you need to pay the service fee,

07. Does it have the risk of being damaged during the delivery?

The machine is wrapped in the plastic film for waterproof, and then put in the standard wooden case for export with foam for shockproof, and nailed at last. It has little risk of being damaged.

08.What about your MOQ?

MOQ: 1 Set

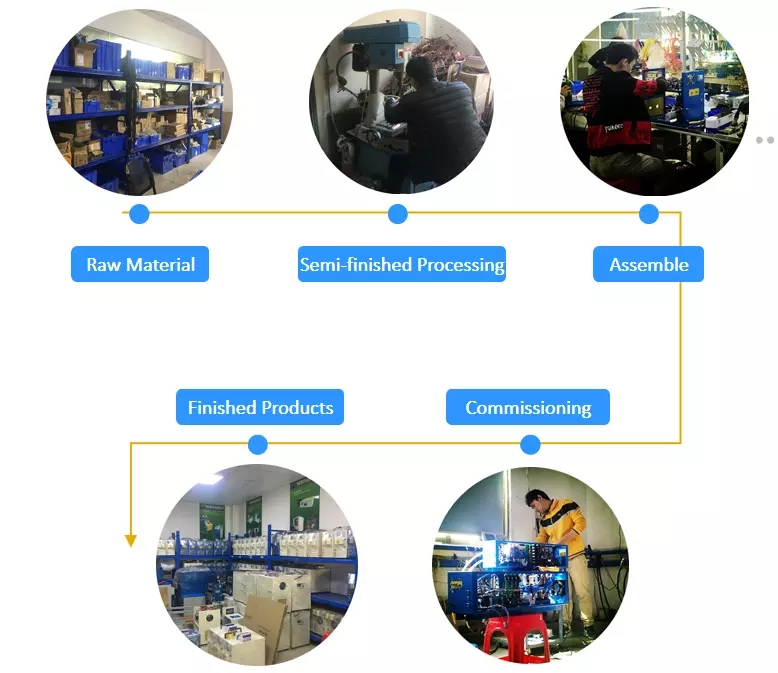

09. Do you test all your goods before delivery?

Yes, we confirm a 100% test before delivery.

Our Services

1. Inquiry and consulting support,answer your request within 24 working hours. (Free)

2. Support Free sample testing.

3. experienced staff will answer all your questions in fluent English

4. Customized design is available

5. The exclusive and unique solution can be provided to our customers by our engineers, there are trained and professional engineers and staffs

6. Special discount and protection of scales designed for our distributor.

After-sales service:

1. One year free replacement components

2. life-long technical support and installation guide

3. The only charge a little money for the replacement of components during the guarantee has expired

Why choose you?

1. Over 20 years experience in induction heating field.

2. Heating furnace is safety and reliability, long life.

3. Our heating equipment export to Italy, Mexico, Turkey, Slovakia, Pakistan, Iran, Vietnam, India, Malaysia, Brazil, Indonesia, South Africa, etc. And winning great popularity.

4. One year warranty and lifetime technology support.

5. Fast, timely delivery & reliable after-sales service.

6. Spare parts & tools delivered with harvester for daily maintenance.

7. Customers first & reliable quality.

Why are you still hesitating and waiting for? Contact me and get a free and professional workpiece evaluation plan immediately!

Contact Us Now !

Pls add my Skype ID : andrew6682527

WhatsApp : +8613113688127

QQ: 2996496980

We can chat online!

Scan the QR Code and to add me on WeChat

Get a Quote

Cataloge

- High Frequency Series

- Medium Frequency Series

- Ultrahigh Frequency Series

- KGPS Generators Series

- Induction PWHT Machine

- Induction Billets Heater

- Hot Forging Furnace

- Induction Melting Furnace

- Gold Melting Furnace

- Air Cooling Heater

- CNC Hardening Tools

- Tube Bending Machine

- Handheld Induction Heater

- Induction Bearing Heater

- Induction Heating Coils

Contact Us

Contact Person:Andrew

Cell phone::+8613113688127

Email:[email protected]

Company Name:SHENZHEN FENGTAI INDUSTRIAL CO,.LTD

Address:Guanguang Road, No.1056,GuanLanTown ShenZhen, China